The external beauty of the ceiling covering is only its visible part. For a comfortable stay indoors, it is necessary that the wooden ceiling be made in accordance with all the rules. So, it must be insulated, have a soundproof layer and be protected by a vapor barrier. All this will ensure a long service life and the right microclimate in the house. In the article we will talk about the device of a wooden ceiling with your own hands.

A properly executed wooden ceiling consists of a heater, a membrane and a sheathing material. Let's consider separately each layer of the construction of the "pie".

Wood ceiling vapor barrier

- Vapor barrier of wooden floors is an important point in the construction or renovation of houses and apartments. It is designed to protect the insulation from the formation of condensate, which means extending its operation without losing important characteristics. Thanks to modern roll materials, this process does not take much time, and it is easy to do it yourself.

- Even when wooden logs are treated with protective compounds, the steam that inevitably forms in residential premises begins to destroy them. And cotton pads can get wet. It is especially dangerous if ordinary sawdust was used for insulation (which is quite common), there is a high probability of mold forming in them. Therefore, it is recommended to make a vapor barrier layer not only in bathrooms and kitchens, but also in all rooms.

- To date, there are membrane fabrics that not only protect against steam, but also create a heat-insulating layer. And for a house with an uninsulated attic, it is recommended to use special hydro- and windproof membranes.

Tip: it is important to make the vapor barrier layer as high quality as possible. Not only leaving the necessary allowances, but also gluing all the joints. With a significant difference in temperature inside the house and outside, a partial pressure is formed. Which drives steam with greater force to drive up, looking for all the cracks in the ceiling for its penetration.

Vapor barrier for wooden ceilings

In fact, membrane fabrics are identical in composition and are equally suitable for both wooden floors and concrete or metal ones. Even at the stage of preparatory work, you should figure out which type is needed for a particular case and in what price category. For vapor barrier, depending on the purpose of the room, use a plastic film or reflective breathable materials.

- Film. Due to its low price and availability, it is very popular. It is used in the construction of country houses, baths and the repair of apartments in houses with wooden floors. When installing, you must constantly monitor its tension so that there is no sagging. In addition, to ensure ventilation, you will have to leave gaps. Otherwise, condensation will form in the heaters. Most vapor barrier films have different sides, one of them is rough and the other is smooth. When installing it, make sure that the smooth side is facing outward.

- Membrane. This is a modern high-tech material. She, protecting from steam, also performs the function of a hydrobarrier. They are divided into 4 main categories: single-sided, double-sided, single-layer and multi-layer.

- Reflective materials. Quite a few species belong to this species. But the most popular and well-known are kraft paper and foil. The latter is used in saunas and baths, for long-term retention of high temperatures. The characteristics of the foil vapor barrier indicate that without changing the physical and mechanical properties, it can withstand up to 120 degrees.

Do-it-yourself wooden ceiling vapor barrier

- Vapor barrier can be carried out before or after insulation. Each case has its own advantages and disadvantages.

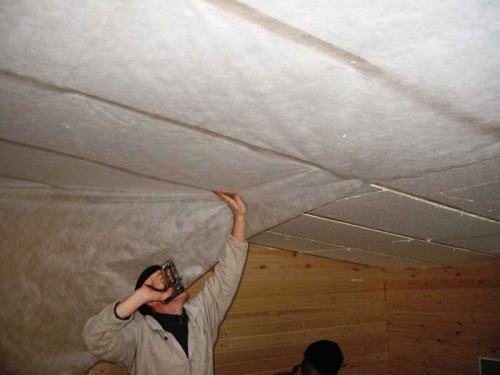

- So, if the insulation will be made with soft or loose material, then first you need to stretch the vapor barrier layer from below. In addition, nothing will fall on the head and eyes. Therefore, when building a new house, this sequence is chosen.

- Another thing is if repairs are being carried out or there is no access to the upper room. Then the vapor barrier is mounted after the insulation layer.

- To work, you will need a construction stapler, adhesive tape, a screwdriver and fixing profiles (or rails).

- First, the width of the ceiling is measured, the vapor barrier is measured and cut off with allowances of 10-15 cm on each side. Starting from the corner, it is applied to the wooden beam of the ceiling and fixed with a stapler. To avoid skew, it is recommended to attach the opposite corner of the same side.

- Do not forget that the canvas is stretched with maximum tension.

- When the corners of one side are fixed, the stapler runs along the entire length, after which, pulling the fabric as tightly as possible, they begin to cling to the second side.

- The next canvas is attached according to the same principle with an overlap of 10 cm on the previous one.

- After the entire ceiling has been passed, all the resulting transverse seams are glued with adhesive tape.

- Then the prepared slats are taken and screwed to the logs, thereby strengthening the fixation points with a stapler. On this arrangement, the vapor barrier is ready.

- Sometimes, during work, you can accidentally break an already stretched vapor barrier. You can’t leave it, but you have to make a patch. A piece is cut out of the fabric with allowances of 10-15 cm. It is placed inside the hole, all edges are smeared with superglue. On top of the incision itself is still glued with adhesive tape.

Manufacturers of vapor barrier materials

- Penofol. Composite multilayer material made of polyethylene foam, one or both sides of which is covered with a foil layer. He copes with three tasks at once: heat, steam and waterproofing of the room. There are several varieties:

- "Penofol A" is the main one in the line, the main function of which is vapor barrier. Has a foil finish. The most budget option;

- "Penofol B" has the same characteristics as the previous one, but is foiled on both sides;

- "Penofol C" one of its sides is self-adhesive;

- Perforated "Penofol" has high thermal insulation characteristics.

- Izospan. Membrane fabric produced in rolls. Depending on the marking, it is used for internal vapor barrier of a room or for wind protection of external walls for cladding. Has a front and back side. One protects against the penetration of steam, and the other does not prevent the penetration of excess moisture. Thus, a favorable microclimate is created in the room and you don’t have to worry about the safety of structures and materials. Today it is the most popular material for vapor barrier of a wooden ceiling.

- Alucraft. The main layer is polyethylene, on one side it is covered with a foil coating, and on the other with kraft paper. Great for lining the ceiling with clapboard.

- Armofol. It is fundamentally different from previous models, as it consists of a glass mesh. Indispensable for vapor barrier in rooms with high humidity and temperature (baths, swimming pools, bathrooms). On sale you can find this material with a self-adhesive surface.

How to insulate a wooden ceiling

Methods for insulating the ceiling are divided into two types: work is carried out from the side of the living space or from the outside (from the attic or upper floor). Decisive, as in the case of vapor barrier, will be the conditions under which the work takes place. Either this is a house under construction, or a renovation in an apartment with a wooden ceiling.

When insulating from the side of the room, you will have to significantly sacrifice the height of the ceiling. If thermal insulation is carried out on an unheated attic ceiling, then additional waterproofing of the material will be required.

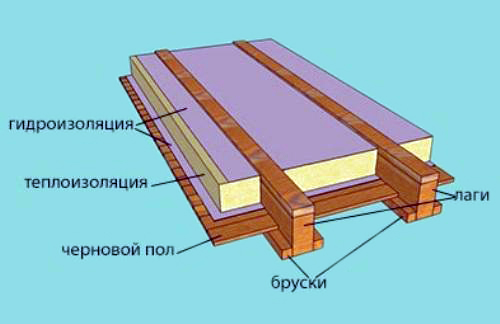

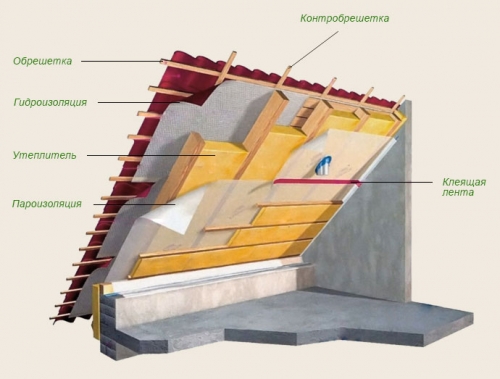

Insulation of the wooden attic ceiling, the pie will look like this:

- roofing material;

- crate;

- vapor barrier material for external walls;

- thermal insulation;

- vapor barrier for rooms (usually marked "B");

- clean finish.

Insulation of a wooden ceiling with foam

Due to its low weight, low cost, easy installation and good thermal insulation characteristics, it is often used to insulate the ceiling from the outside. But due to low environmental friendliness, it is not recommended to use it indoors.

Stages of work

- It is convenient if the size of the foam sheet matches the distance between the wooden logs. In this case, the warming process will be quick and without unnecessary debris. But if it is necessary to adjust the material in size, it must be taken into account that although it is cut quite easily, the blade blunts very quickly. And then it is very difficult to get rid of the garbage formed during this.

- Styrofoam is attached to the ceiling with a special glue, which resembles tile in consistency. It is applied pointwise in several places or covers the entire surface. When gluing the plate, you need to press and hold it for a couple of minutes.

- For greater reliability, it can be fixed at 5 points with self-tapping screws with mushroom caps. If joints are formed, they are covered with mounting foam.

Insulation of a wooden ceiling with ecowool

This modern eco-friendly material is based on cellulose with various additives. Basically, it is recycled paper. But the output is a heat-insulating material with excellent characteristics. It is often used for warming the interfloor ceiling and the whole house. It is environmentally friendly, cheap, and a team of professionals with a special inflatable cannon can insulate a box of 150 squares in 1 working day.

Stages of work

- To insulate a horizontal ceiling surface, you do not need to hire specialists or rent expensive blowing equipment.

- From below, the ceiling should already be sheathed with boards and have a vapor barrier layer. Ecowool is poured directly from the bag, evenly distributed and, if possible, compacted tightly. The better this is done, the less likely there will be further shrinkage. It is necessary to fall asleep in several layers and ram each of them. Everything, on this work on the insulation is over.

Insulation of a wooden ceiling with expanded clay

This is an ancient fired clay material. It has high thermal insulation properties and low weight. It is used everywhere, up to the manufacture of expanded clay concrete blocks for building a house, which are distinguished by their energy-efficient features.

Stages of work

- As with any bulk insulation, work is carried out from the side of the second floor or attic. Expanded clay is poured onto the logs prepared and covered with a film. The smaller it is, the better. Since it is more tightly adjacent to each other, leaving less air spaces.

- After backfilling, it is rammed. And then you can go in two ways. If the ceiling is insulated in a country house, then backfilling is enough and you can lay the floor. For a country cottage, whose floor beams are strong and can withstand a lot of weight, it is recommended to make a concrete screed with a reinforcing mesh.

Insulation of a wooden ceiling with sawdust

They are chosen by adherents of natural materials or those who want to save money. This method is more laborious, as it requires preparatory work. But in general, it has been tested over the years and rightfully deserves attention.

Stages of work

- First of all, you need to prepare a mixture of sawdust and cement for insulation. To do this, it is best to choose medium-sized chips, and not sawdust. It is desirable that the material is already stale and treated with an antiseptic composition. Most often, the chips are soaked for a day in an aqueous solution of copper sulphate, after which they are well dried.

- Calculating the required volume of sawdust is simple. It is enough to multiply the insulation layer of 15-20 cm by the ceiling area.

- Now prepare the cement milk. In a convenient container, cement is mixed with water in a ratio of 1:10. After the solution is ready, chips are poured into it and mixed until a homogeneous mass.

- By the time the mixture is prepared, the ceiling should already be ready for insulation. To do this, the floor is dismantled from the attic, the entire space between the lags is cleaned and the wooden structural elements are treated with special compounds. A dense film is laid on the bottom as a single sheet. The overlaps are glued.

- The insulating mass is evenly laid between the lags and rammed. When it is completely dry, it will be possible to walk on it.

This is the cheapest way to insulate a wooden ceiling. Sawdust or shavings are given free of charge at all sawmills, and cement consumption is very small.

Insulation of a wooden thread in an apartment with mineral wool

Mineral wool is the most popular way to insulate a wooden ceiling. It does not require the preparation of the composition, its heat and sound insulation characteristics are higher than slab counterparts. It is environmentally friendly and affordable. The cost depends on the density, so the softest and cheapest cotton wool is sold in rolls. But its installation will be more difficult. Accordingly, more expensive high-density rigid mats, but even one person can insulate them.

Tip: despite the environmental friendliness of mineral wool, it is recommended to work with it only in protective clothing and a respirator. When it comes into contact with the skin, particles of the material cause severe itching, which will be very difficult to wash off. And clothes, after working with him, are thrown away.

Stages of work

- The width of the plates is 60 cm, which, as a rule, is equal to the width of the distance between the lags. Therefore, they are simply inserted into this space. The thickness of the plates is 5 cm, 3 or 4 layers are made for insulation. They are arranged in a checkerboard pattern to prevent the formation of cracks, and in the case of insulation of the attic stream - cold bridges.

- After installation, it is tightly tightened with a vapor barrier fabric from the side of the living room, so that the mineral wool does not sag.

wood ceiling finish

Before proceeding with the decoration of the ceiling, it is necessary to take into account the features of wooden structures:

- not only new buildings shrink naturally. But even when the seasons change, they can “walk”. This is due to the property of wood to absorb moisture or give it away. Why often cracks appear on its surface (the exception is glued laminated timber). Therefore, when puttying a wooden ceiling, there is a high probability of cracks;

- if the house was built a long time ago, then its walls "breathe". And this does not always indicate the excellent vapor-permeable properties of wood, but also the fact that cracks have appeared in the ceiling or walls. In the cold season, this can adversely affect the stretch ceiling;

- the wooden ceiling belongs to the fire hazardous class, therefore it is recommended to use materials with high fire-resistant characteristics or treated with antipyretics for its cladding;

- wooden floors make a limitation on the possible load on them. For example, a bath is recommended to be placed only on the first floor.

But in general, a wooden ceiling does not limit its decoration. It is permissible to use all the same materials as for concrete floors. But more and more modern designs are designed to emphasize the beauty of the tree, rather than hide it.

Wooden ceiling photo

- The easiest way to sheathe a wooden ceiling with suspended structure. It will hide all the irregularities of the base, and thanks to the mobility of the structure, you do not have to worry about the shrinkage of the house. In addition, this will hide all communications and make additional insulation. But this will lower the ceiling height by 10 cm.

- The same advantages are also stretch ceiling which, despite their artificial origin, harmoniously fit into the interiors of modern wooden houses. True, their installation will require hiding the wiring under the ceiling space, which is not recommended in wooden houses. It is important that all wires are hidden in a protective corrugation.

![]()

- When the task is to create an atmosphere with a beautiful wooden ceiling, you should use decorative beams. They are light false structures hollow inside, which will allow you to hide communications in them. They are made from natural materials or plastic. Finishing them will decorate the wooden ceiling, allowing you to leave the floor boards in sight. A variety of their designs will not be difficult to choose the right option. Fastening is carried out on self-tapping screws using bars.

- But the most popular both in country houses and in country houses is lining. It comes in different price categories, which depends on the type of wood and the quality of the material (the presence of knots). Despite the fact that its ceiling decoration seems to be an outdated option, with some design tricks it opens up in a new light. For example, when painting it not with varnish, but with white paint, it looks fresh, modern and is able to expand the space. It also looks beautiful in combination with massive false beams. Thanks to the locking method of connection, its installation is simple and fast. The result is a smooth, beautiful wood finish.

- Often, cladding is chosen for a wooden ceiling. drywall. It has special refractory sheets, which, although more expensive than usual, are recommended for use in such cases. In addition, it is an environmentally friendly material with high vapor-permeable properties. It is plastic, suitable for sheathing rounded ceiling structures. It is chosen when it is necessary to bring a touch of modern urban design to the interior of a wooden house. It looks great in combination with wooden ceiling elements.

- If you use cheap boards for the ceiling, but you want to have a wooden ceiling, then you can buy block house. It imitates the surface of rounded logs or timber. One panel has a relief of two or three slats. It is made of solid natural wood, therefore it is universal in use (suitable for ceiling sheathing on a veranda or in an arbor). In the interior, such a ceiling looks primitive and very atmospheric. But the high price of such a wooden ceiling makes it less popular than clapboard. They fix it on the crate, the panels themselves are fixed with locks.