All photos from the article

Sawn logs are boards,. The task of competent and efficient sawing of trunks is extremely relevant for independent or industrial logging, in addition, knowing the basics will help you choose the right lumber.

We will look at the main points regarding this topic and tell you how to properly cut a log on a band sawmill.

sawing logs

The main task

Important! The sawing scheme is selected in accordance with the quality of raw materials, the purpose of the board and the capabilities of the equipment.

Sawing tool

Logging is done with a special tool. For normal work by today's standards, you need a special machine for cutting logs with your own hands, which is called a sawmill.

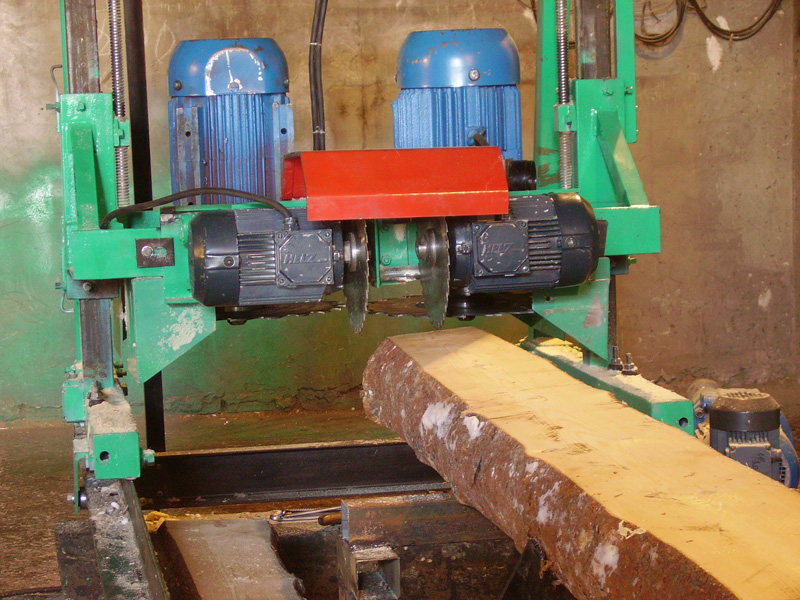

There are two types of sawmills: disc and band sawmills. Circular saws use circular saws and are considered less efficient, as they have a large cut thickness (from 6 to 9 mm), less accuracy and depth.

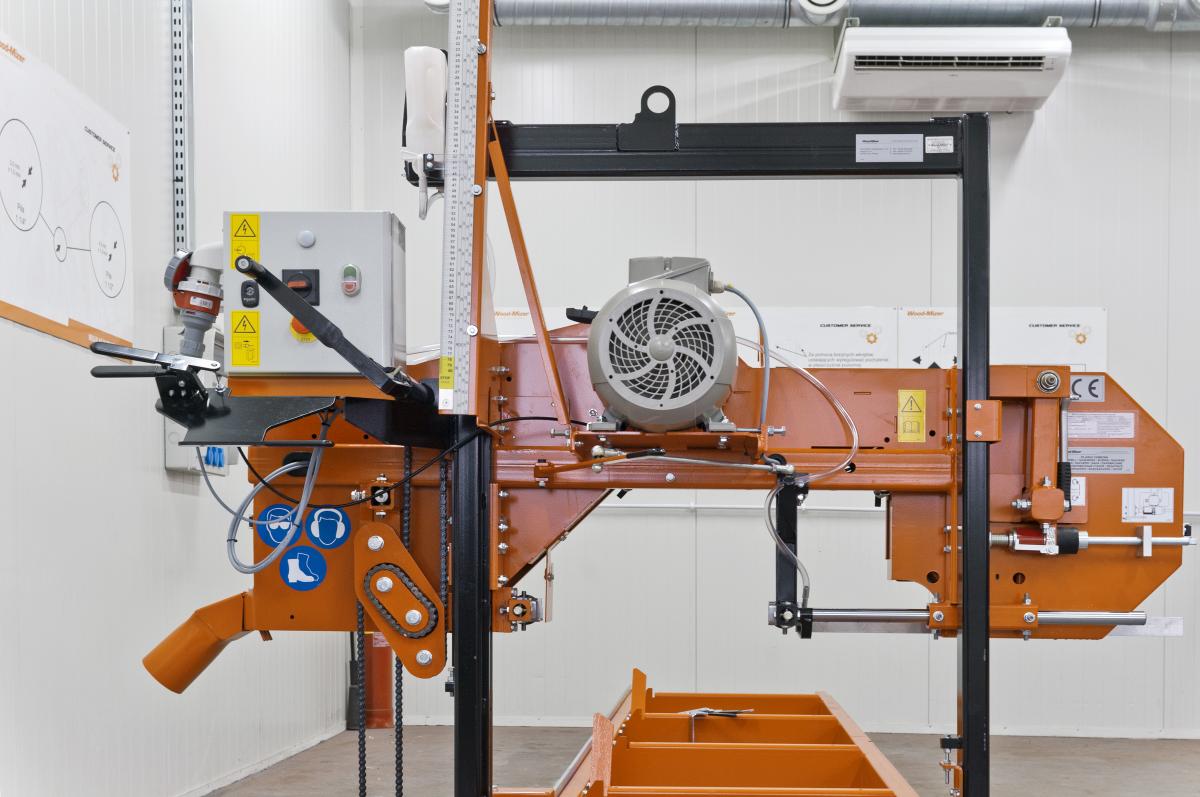

The band sawmill is equipped with a different system: the saw is a band worn on rotating rollers. The cut thickness is approximately 1.5 - 3 mm, which is quite economical in terms of chip removal.

Modern models are characterized by high accuracy and productivity, they are automated and have a tilting mechanism for lifting and turning logs in case of circular sawing or sawing timber.

Using a chainsaw, you can only cut a log in half, but if you use a special frame, you can dissolve the log into boards right in the forest.

Important! Band sawmill is considered the most efficient and cost-effective.

Conclusion

Sawing a log is considered one of the most complex and important tasks in logging and lumber production. The quality of products and the income of the enterprise depend on the chosen scheme, well-designed work procedure and tool preparation.

The video in this article will tell you about the types of sawmills and how to cut wood.