The facade of a wooden house has a number of unique features that should be considered when choosing the right cladding material. Finishing should be chosen not only on the basis of the parameters of building structures, but also depending on the functions that the facing layer should perform.

What should be the lining

For facing the facades of wooden houses, it is necessary to use facing materials that will simultaneously perform decorative, protective and insulating functions.

The decorative function of cladding is the most important for many owners, and this is not surprising, every person wants his house to be beautiful, attract attention and stand out from other buildings. The modern market of finishing materials includes a variety of claddings of different colors and textures, with the help of which any design project of a building can be put into practice. It should be noted that the decorative function is typical for facing the facades of any buildings.

Unlike concrete walls, wooden structures need protection from insects and rodents, which can cause serious damage to wooden walls. If this problem is not solved quickly, then the supporting structures of the building may receive irreparable damage, due to which their service life will be significantly reduced. To reduce the negative impact of pests, the finish must provide reliable protection against them.

Wood is a visually attractive material, which, at the same time, is not particularly resistant to external negative influences. Moisture is a serious danger for wooden structures. Under the influence of precipitation, the walls of such buildings can begin to rot.

When choosing a facing material, it must be taken into account that wood must "breathe", therefore, materials with high vapor permeability characteristics are usually used for coating.

Wood finishes

Many cladding materials available on the market can provide high-quality protection to wooden walls from any external negative influences, save wood from decay and pests. Among the most modern and popular among the owners of the options for finishing the facades of wooden houses, it is possible to single out a system of a ventilated facade and a “wet” finish.

"Wet" finish

"Wet" facade finishing method great for houses built from frame panels and timber. Finishing technology may include additional insulation of external walls. Although thermal insulation is not mandatory when finishing the facade in a “wet” way, the benefits of installing additional insulation are so high that most owners do not refuse additional financial expenses.

"Wet" finishing method

"Wet" finishing method “Wet” finishing technology involves priming wooden surfaces, gluing insulation material plates to them, after which, on top of the heat-insulating layer, the wall is finished with high-quality plaster. An additional reinforcing layer is usually installed between the insulation and the plaster finish, providing additional reliability and durability of such a finishing structure.

"Wet" methods of finishing exterior walls have been used for a long time. Due to the possibility of additional insulation, this cladding option is most widely used in North America and northern European states. Installation of all finishing elements is quite simple, it is quite possible to cope with such work on your own, without turning to professional construction companies for help.

To ensure the greatest reliability and durability of the finishing layers, before installing a "wet" facade, a thorough leveling of the external walls of the house is usually carried out. For some wooden structures, it is possible to align the walls well only by installing plywood sheets or a plasterboard base, which can make the installation of the finish somewhat more complicated.

When choosing a "wet" finishing method, the home owner must take into account that this technology, in its essence, is a rigid system that can collapse due to fluctuations in the volume of wood.

Hinged ventilated facade

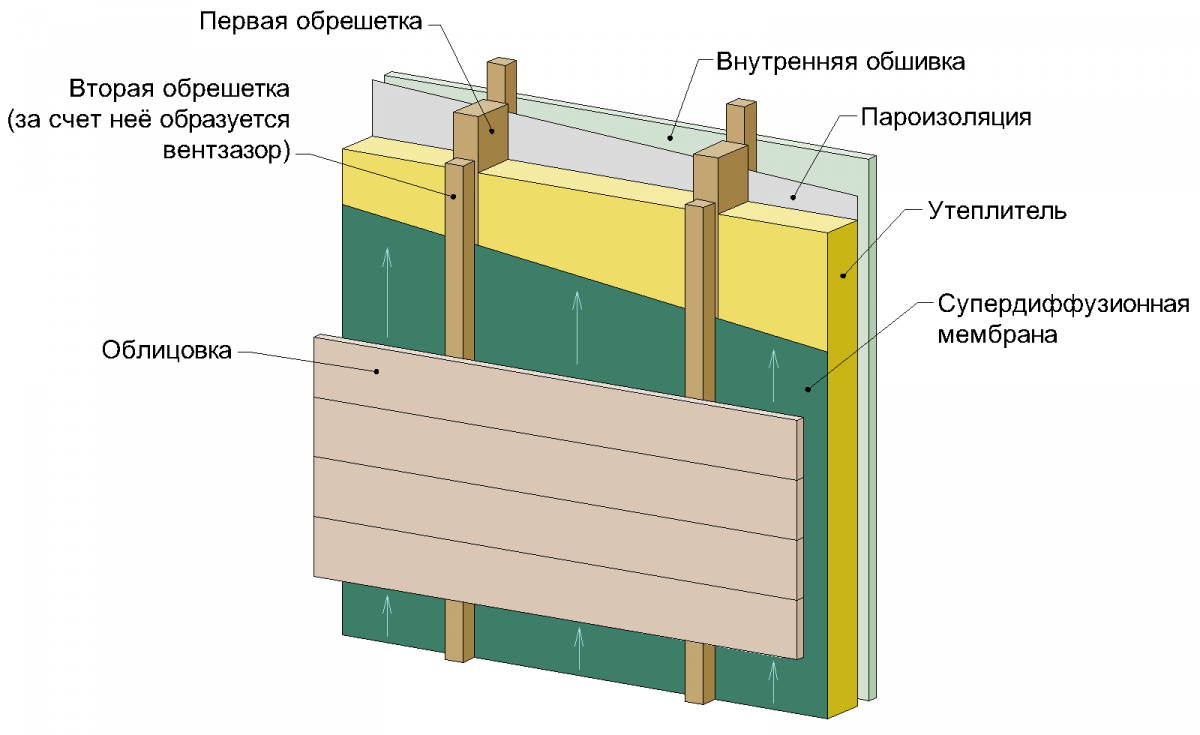

Ventilated facade systems, today, are considered the most modern option for finishing exterior walls. Such systems consist of several separate layers - frame, insulation and exterior finish. During installation, all elements of the ventilated facade are installed in such a way that a small empty space remains between the insulation (or wall surface) and the outer facing layer. It is through this space that the ventilation of the wall surfaces is carried out.

Scheme of a ventilated system

Scheme of a ventilated system Ventilated facades have many positive qualities. Such cladding options provide the highest level of heat saving, allow you to seriously save on electricity and heating. The outer facing layer of the ventilated facade can be made from a variety of finishing materials - siding, porcelain stoneware slabs, fiber cement panels, etc. Such a wide variety of finishes allows the owner to implement even the most daring design projects.

When arranging the facing layer with the help of hinged structures, the owner you need to take into account the condition of the bearing walls and the foundation of your home. Not every private house can withstand the additional load in the form of a galvanized steel frame and a facing layer of porcelain stoneware panels. Thanks to a wide choice of facing materials, ventilated facades can be installed on almost any building.

If the walls of the house cannot withstand the additional load, you can use aluminum instead of a steel frame and choose the lightest facing material for the outer layer.

According to its technical characteristics, the ventilated facade system surpasses all other options for finishing private houses, however, it also has some disadvantages. Among the main disadvantages of ventilated facades, their high cost and the impossibility of installation without the help of specialists are usually distinguished. Recommendations and advice from professional builders may be required not only for the construction of the main structures of a ventilated facade, but also for determining the condition of the outer walls, the ability of structures to withstand additional loads.