Whatever construction you plan, you will definitely need wood materials. And all the work will be much cheaper if you prepare the lumber with your own hands. Therefore, in this article we will look at how to saw a log into boards on our own.

Sawing methods

To cut a log into boards, you can use one of three existing methods:

- Along;

- Across;

- Obliquely - since this method is used extremely rarely (in specialized developments and projects), then we will focus on the first two methods.

cross cut

It is carried out to obtain parts in the form of cylinders and disks.

Longitudinal cut

Apply such a dissolution of logs on boards, slats, beams. At sawmills, furniture factories, procurement enterprises use many different devices. We will consider how sawing logs into boards at home is carried out.

At home for sawing, you can use a saw, a grinder with special nozzles, a circular saw.

Cutting preparation

Before, , you need to remove the peel from it. This can be done with a sharpened shovel, scraper, electric planer.

When using a shovel, movements are made from oneself.

It is believed that the best result is obtained when the bark is removed with a scraper - it does not affect the tree.

How to cut a log into boards

options, how to cut a log into boards, are different. Everything depends on your needs. The sawing technology itself is as follows:

- The bark is removed (but at home this can be done later);

- A log is fixed on the frame or guides;

- One is sawn off to get a flat surface;

- Then they put it on a bed (table) with a flat surface, fix and saw off the second slab;

- Dissolve all the logs on the boards.

Crosscut log

This is not difficult even for work at home. Lay the log on the trestle or secure it on rails. And you can cut off pieces of the desired size.

Longitudinal cut log

The difficulty of such a cut is that the same thickness must be maintained along the entire length of the log. It is best to use special equipment for these purposes, which is mounted on a log.

Sawing logs into boards at home

Many for sawing logs make a sawmill with their own hands. Consider two main options for their manufacture.

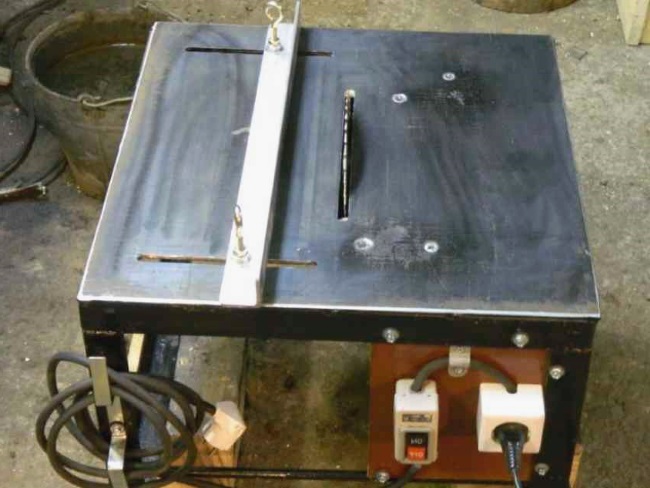

- From metal plates and squares, weld the frame, attach the engine to its lower part. In the upper part, put the shaft with pulleys. Then attach one or more saw blades to the shaft. Fix the guide from a metal square or timber on the table. Pressing against the guides, feed the log and move forward. If you use one saw, then you need to attach a ruler or markup on the surface of the table.

- Weld the frame from the profile pipe and channels. or electrically attached to a vertical feed carriage. To make the dissolution of logs on boards as accurate as possible, attach a ruler to a vertical stand. As a carriage guide, use a rod or ground tube. They are necessary in order for the carriage to move vertically. Install a screw in the bearing that will move the carriage when moving. Also, do not forget to prepare clamps for the log.

When using the second option for work, it is the saw that is set in motion, on a specially attached frame. The log itself remains in place. If you're using a reciprocating saw rather than a chainsaw, the process is a bit slower because it only works in one direction.

How to cut a log into boards with a circular saw?

To cut a log into boards lengthwise, you can also use a circular saw. But you need to take into account the factor that the log can spin from side to side or jump.

To avoid the inconvenience associated with this, we advise you to attach a fin that will separate the future board from the log and prevent the log from swinging during sawing.

Tatyana Kuzmenko, member of the editorial board of the Sobcorrespondent of the online publication "AtmWood. Wood-industrial bulletin"

How useful was the information for you?