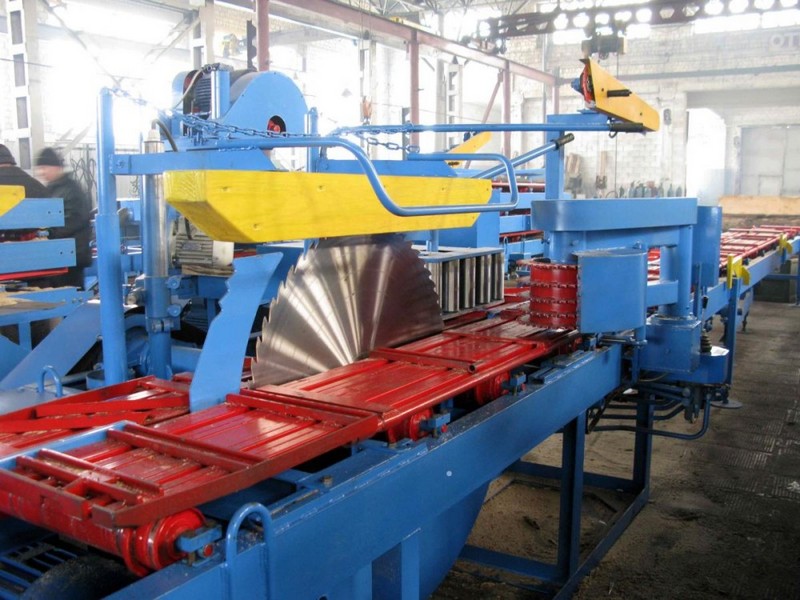

The band sawmill is a compact unit, the main component of which is a band saw. Sawing logs on a band sawmill, as a rule, is used in woodworking or repair and construction industries.

Advantages and disadvantages

Today, horizontal band sawmills are one of the most promising woodworking devices for sawing round wood. Their advantages are as follows:

- economy in operation;

- minimum energy consumption;

- excellent maneuverability;

- a good yield of material (about 70%);

- the possibility of private cutting of each log.

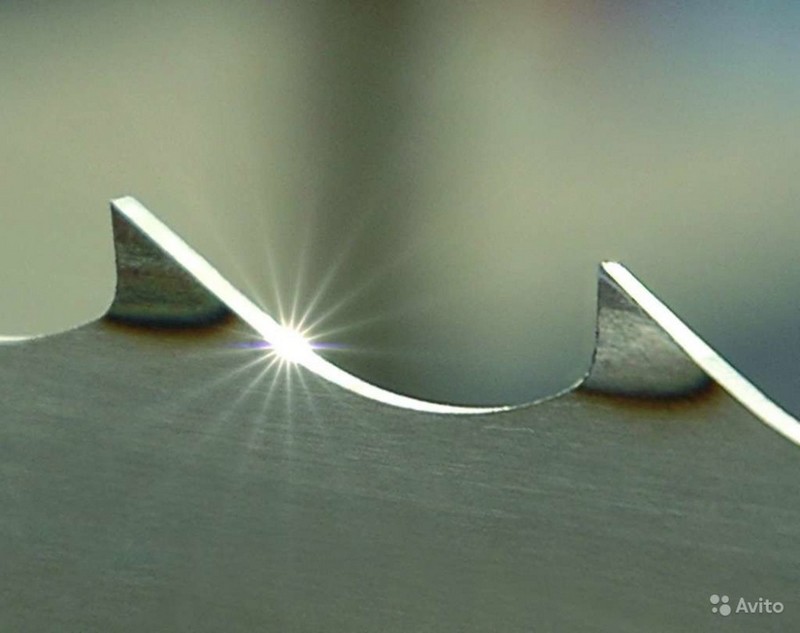

Among the shortcomings, one can identify such points as the low accuracy of the radial cut, low throughput, as well as the appearance of a “wave” due to increased resinousness and the release of a significant amount of moisture from a freshly sawn coniferous tree. To get rid of resin sticking to the cutting edges of the electric saw and to the moving components of the sawmill, intensive lubrication with special solutions and regular change of cleaners helps.

However, despite all these shortcomings, the use of band sawmills in small and medium-sized businesses in terms of woodworking is very popular. Their acceptability for the price and receiving from a band sawmill on average 20-25% more commercial wood, unlike traditional sawing honey, make such sawmills very competitive and extremely profitable when sawing logs in a private, small business.

Types of sawing logs

How to cut a log correctly to get an optimized lumber yield? You need to choose the right cutting pattern. This action is due to various factors: the type of wood, the volume of logs, the aggregate system and the grade of lumber that will need to be produced. In addition, it should be taken into account how the lumber will be trimmed in the future.

In practice, the following 3 schemes for the classic sawing of a log at a sawmill are known:

- Sawing a log in a circle. This sawing configuration is beneficial for medium to high quality logs. First, a cut is made, then the log is turned over to a new edge, then sawn again, and turned over again, and so on until at best 5 turns occur.

- Elementary sawing of a log (or ordinary sawing through). It is rational to use a similar scheme for low-grade wood. The resulting lumber will be more prone to warping during drying, unlike the first scheme, and will also come out heavier and drier with more residue, since each element will then still need to be sawn on the sides. In this model of sawing, the log is sawn until the central part of it opens. Then it turns 180º and is finished to the end.

- Sawing timber. This sawing combination is generally used when working with medium to large wood. In this case, the log can be of medium or low quality and is sawn in the same way as when sawing in a circle. However, the core part of a log with dimensions of 18x23 cm or 25x25 cm is not sawn. Such a bar is either sold as is, or processed on other units in the technological direction.

When using one or another model for sawing logs, the productivity of the sawmill is increased and time and effort are saved on the production of products of various qualities. (Fig. 1 Sawing logs at the sawmill)

Sawing logs on a band sawmill can be productive and easy, depending on how you approach this process.

By planning in advance efforts and time, it will be possible to cut logs with greater productivity. You can make this process as efficient as possible by following these guidelines:

- When sawing logs, it is recommended to use only sharp saws. An indicator that the saw has become dull will be its frequent pulling up during the cut, because the dull blade heats up and expands, i.e. loses tension. Thus, the saw starts to walk, get stuck in the log, and create problems in pulling it back. A replacement saw in time will help to avoid such situations.

- Avoid breaks. Daily inspection and lubrication of the sawmill takes not so much time compared to the costs that will go into replacing the bearings on the flywheels, as well as the cost of spare parts itself.

- Prepare logs for cutting in advance. Before you start sawing trees, they need to be washed from dirt, using a metal detector, remove possible nails driven into them that could remain in the logs after the signs were removed from them. Before sawing logs, the procedure for trimming knots and protruding nodes on it with a chainsaw will help save time, and you will also need to cut the end of the sawn tree in advance so that it fits as closely as possible to the diameter of the log.

- During the cutting of the timber, it is necessary to immediately produce its edging. It is necessary to cut off the edges immediately after sawing the log into beams directly on the band sawmill: first on one side, and then on the other, and so on until the last board, until the entire process of sawing and processing the sawn log is completed.

Sawing a log on a band sawmill is not so fast, because it is primarily electromechanical equipment, and it tends to overheat, and working it on the edge will not lead to anything good. It is necessary to give a break to the equipment and not to rush - let everything go as it should. As a result, unnecessary experiences will be reduced, and productivity will only increase from this.

More articles on this topic: