It would seem that the question is quite simple - and the methods have long been worked out, and the choice of thermal insulation products is significant. But this is not about any building, but about a wooden house. Regarding its insulation, there are a number of nuances that cannot be neglected.

It's all about some features of such a building material as wood. First of all, it is its susceptibility to decay, the ability to "breathe" and retain heat well. The last two properties allow you to maintain comfortable conditions in the premises, as a rule, without significant additional costs. For example, for the purchase (and professional installation) of climatic equipment, due to the increased consumption of en / resources (including fuel for the boiler). At least, the indicated devices are not used as intensively in wooden houses as in brick or cellular concrete buildings. So, let's consider in detail how and what is the best way to insulate a wooden house.

To make the technology of work clearer, it should be explained why insulation from the outside for a wooden house is the only right solution. This method of reducing heat loss is the main one for any buildings, as it has a number of advantages. For example, does not reduce the usable area. This is one of the disadvantages of arranging this protective layer from the inside. But for a log house, something else is more relevant.

It's all about the so-called "dew point". The external installation of the insulation takes it outside the perimeter of the house, and condensate forms in the ventilated space. Consequently, in cold weather, the tree does not freeze, and in warm weather, the process of decay does not begin. If the insulation is laid on the walls of the premises, then the “point” shifts inward. As a result, the logs (beams) remain unprotected, and the condensate settles in the thermal insulation material, which initiates the development of mold and fungus not only in it, but also in the rooms.

How to insulate a wooden house

If you delve into the details, then the choice of materials is not so big.

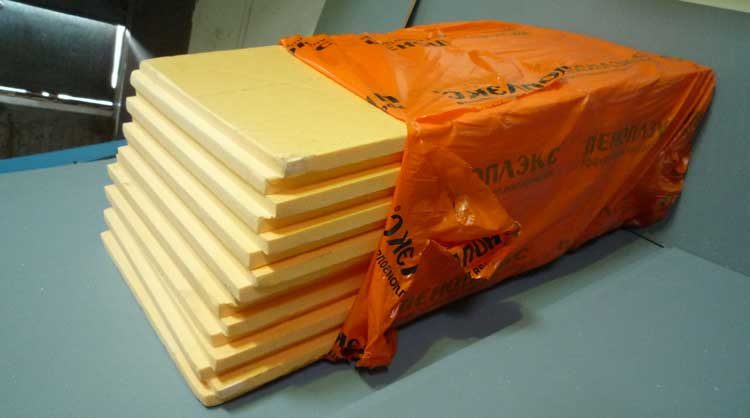

Styrofoam boards

They differ not only in the correct geometry, but also in "rigidity". Therefore, to fix them, it is necessary to carefully align the base. It is still acceptable for a beam, especially if the walls were erected by professionals. And what about logs? In addition, foam plastics do not let in not only moisture, but also air. Therefore, the main attraction of a wooden house - climate control - will be completely leveled.

Spray formulations

Usually polyurethane. There are even more disadvantages, besides, special equipment will be needed. But the companies providing this service (for PU insulation) are silent about another rather significant disadvantage - the low maintainability of the layer. After all, it sticks to the surface on which it is applied. If, in the literal sense, it can still be “picked out” from a brick or concrete goods, then what about the tree? After all, it is quite malleable to mechanical stress, and damage to logs or timber in this case cannot be avoided.

There are other types of insulation for wooden buildings, which are advised to use the authors of some articles. But all the listed materials (chipboard, flax fiber, etc.), taking into account the specifics of the log house and in terms of durability, hardly deserve attention.

To insulate buildings made of wood, only mineral wool should be used. Excellent vapor permeability, elasticity, low weight - in fact, such thermal insulation fully complies with all the main criteria for a wooden house.

Warming the house from the outside - how to do it

Surface cleaning

This is where any repair or finishing work begins. For a wooden house, the initial inspection is especially important. It is necessary to identify all foci of damage to wood, determine their nature, methods and means to eliminate defects. This is a separate topic, and.

Processing with special / preparations

For a wooden house, both are equally relevant - flame retardants and antiseptics. Features of their use and formulation are indicated on the packaging. It is clear that it is desirable to do this in positive weather and clear skies.

All types of wood differ in porosity. Although more often they talk about the hardness or density of lumber. Based on this, the appropriate compositions should be selected. Their list is quite large, and the specifics of the application can vary greatly. The best ones are those that penetrate deep enough into the structure of the material and do not "close" the pores. Otherwise, the tree will not be able to "breathe".

Installation of a vapor barrier layer

Its main purpose is to ensure the ability of wood to self-regulate the microclimate and at the same time protect the material from direct contact with moisture. There are many varieties of films and membranes on sale. If the first option is chosen, then it must be taken into account that all samples differ in their execution, and therefore, in the specifics of use. The film is cheaper, but the usual modification of polyethylene cannot be used for vapor barrier. It is hermetic, and together with water does not let air through. It is worth considering when choosing products.

Mounting on the outside of a wooden house is quite simple - using a construction stapler (staples). It is only necessary to take into account that the strips must be mounted with a slight "overlap", and the joints must be closed with adhesive tape (adhesive tape).

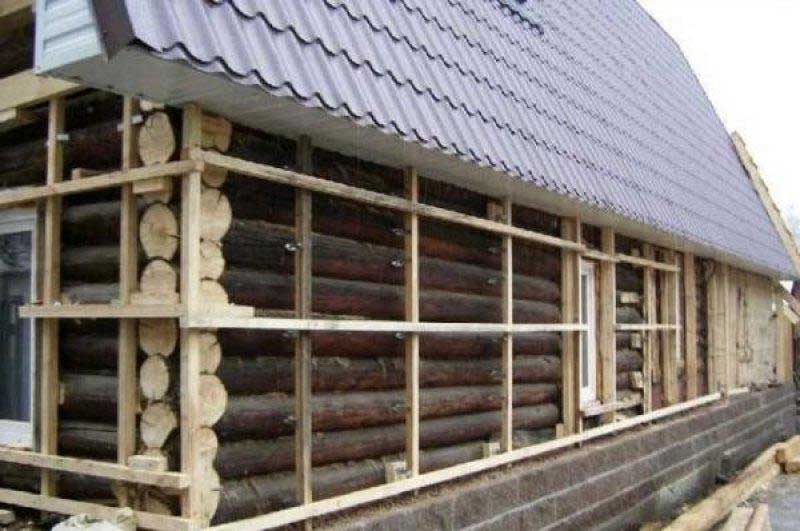

The construction of the supporting frame

It is also called a crate. What is its peculiarity in relation to a wooden house? The coefficients of thermal expansion of the materials to be bonded should be taken into account. Metal slats are much more convenient for installation, but since the house is made of wood, it is not advisable to use them. Only wooden bars of the appropriate length and section.

The dimensions of the seats (cells of the crate), as well as its design, are selected based on the geometry and design of the insulation. Mineral wool is sold in slabs or rolls, so it is not difficult to draw up a sample laying pattern.

Another nuance concerns fasteners. Self-tapping screws or screws should not be used for fixing elements of the crate. They "tightly" grab the supporting structure, and this should not be. A wooden house “plays” somewhat under the influence of external factors (a feature of the material), therefore, fastening the crate to it is only with nails.

What to consider

The reliable position of the insulation is ensured by the fact that during the laying in place, the samples are slightly compressed. Then, due to their elasticity, they straighten out somewhat, which determines their reliable "hitch" with the slats of the supporting frame. When calculating its parameters, it is necessary to choose the cell sizes so that they are slightly smaller than thermal insulation products. Then you do not need any of their additional fastening on the outside of the house.

Laying insulation material

There is nothing complicated about this, especially if the scheme is drawn up correctly. Mineral wool is well cut with an ordinary knife, they bend, so there will be no problems.

Peculiarities:

- On problem areas of the walls (complex configuration, slope, etc.), it is worth additionally fixing the thermal insulation with special nails - anchors.

- The gaps at the junction of the insulation to the frame rails are sealed with the same construction tape.

- Installation of thermal insulation is carried out in the direction from the bottom up, in rows.

- In regions with frosty winters, insulation (depending on the thickness of the samples) can also be laid in 2 layers. In this case, the plates for the second are cut so that after installation their joints in the rows do not match. That is, a mount with a slight offset.

Calculator for calculating the amount of insulation

Using a conventional p / e film will lead to the fact that moisture will begin to accumulate in the insulation. There is nothing to comment here.

Control grille

It is necessary to create the so-called ventilated space. In most cases, it alone is enough to ensure effective removal of liquid due to the natural circulation of air currents.

Details of the counter-lattice are rigidly fixed on the rails of the supporting frame. Their elevation above the latter, as well as what exactly to use as these structural elements, depends on the finishing material of the wooden house. It can be both cutting bars and a metal profile. In this case, thermal expansion is unimportant.

On a note!

- Warming the walls of the house from the outside is only a partial solution to the problem of reducing heat loss. We must not forget about such parts of it as the basement and the foundation (if it rises above the ground). This is where expanded polystyrene comes in handy, and spraying can be done, given the small coverage area, with your own hands. There are special devices, and they are not so expensive. And although in fact they are disposable (despite the fact that the manufacturers claim otherwise), given the reasonable price, it is possible to implement such an option for warming the outside of the lower part of a wooden house.

- When choosing a variety of mineral wool, it is advisable to focus on products of the "eco" category. From all points of view, for houses made of wood - this is the best option.

Have a warm home!