And although wooden buildings look very beautiful and rich, they also need to be insulated from the outside. This will not only create reliable protection from moisture, but also from the cold. Installation work is not particularly difficult, but if you do not have the necessary experience in this matter, it is better to seek help from a specialist.

A wide selection of thermal insulation materials allows each owner of a wooden house to choose their ideal option, taking into account cost and performance.

stone wool

Cutting this material can occur even with a conventional knife. Since the plates are lightweight, they are very easy to transport even in a passenger car.

stone wool

stone wool When laying stone wool, it must be installed in the space between the racks of the crate, and then the vapor barrier material from the inside and the waterproofing layer from the outside should be laid.

Ecowool

This material is characterized by its environmental friendliness. In its manufacture involved cellulose fibers. Produced in compressed packaging. The process of warming the material in question can occur in several ways:

Styrofoam

This material is considered one of the most inexpensive. It does not absorb moisture, so when installing it, care must be taken to lay a moisture-proof membrane. When working with foam, maximum accuracy is required, because it can crumble and break.

Styrofoam

Styrofoam

It is sold in the form of two-component substances. They foam when applied under the influence of air. The principle of applying this heat insulator is similar to mounting foam. With its help, all the voids in the wall are filled. Excess material is cut off.

Thus, it is possible to obtain a monolithic layer of insulation that will not allow heat to escape from the house. Also, polyurethane foam is characterized by water-repellent properties.

Natural heaters

This category of heat-insulating materials includes slabs of straw and clay, sawdust. They are distinguished by their environmental safety, cheap cost. Their main disadvantage is the complexity of manufacturing. Linen fiber should also be attributed to natural insulation.

sawdust for insulation

sawdust for insulation The material has excellent antiseptic properties, prevents the formation of fungus and mold. It is easy to cut, install and does not cause the development of allergies.

Installation work

The installation process of the insulation is different depending on which material option was chosen. If the heat insulator is presented in the form of mats, then the installation involves the following steps:

- Treat the surface of the wooden wall with antiseptic compounds. This should be done in two layers, paying special attention to the corners and the bottom crown. The ends of the logs should be treated more carefully, since they are often subject to decay. Such actions are carried out in warm weather. After that, you need to wait 1-2 days.

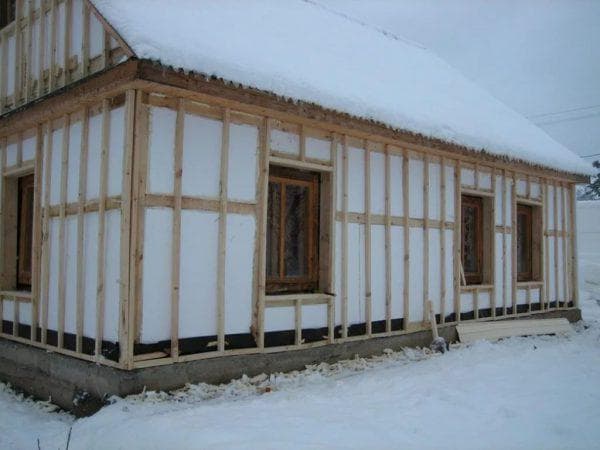

- Using staples, fix a stapler waterproofing film with a vapor-permeable coating on the walls. Attach the joints of this material with an overlap and glue with mounting tape. Fix a vertical frame of boards on the film, the thickness of which should be equal to the thickness of the heat insulator. The step of the crate should be 3-5 cm less than the width of the heat-insulating mats.

- Mount a heat insulator on the film between the boards, while pressing it a little. The final fastening of the material is carried out using anchor nails. If it is required to lay insulation in several layers, then the next layer must be laid with offset seams. Then the top layer will overlap the joints of the bottom ones.

- Fix a hydro-wind-protective membrane film over the heat insulator with staples. Fasten the joints with an overlap and secure with tape.

- On top of the film, make a device for a ventilated frame. Boards are also used to create it, guaranteeing a distance between the heat insulator layer and the decorative facade of at least 5 cm.

- Fixing the boards to the lower frame is carried out using self-tapping screws. If the wall surface is uneven, then it is worth using perforated hangers for the profile. Thanks to them, it is possible to adjust the distance to the crate. For finishing with metal siding or corrugated board, it is worth using a drywall profile instead of a board.

- The cladding is fastened according to the technology recommended by the manufacturer.

On the video, how to properly insulate a wooden house from the outside:

If the house is lined with bricks outside

If a wooden house has a brick cladding, then it can be insulated from the outside using various heat-insulating materials. When choosing a suitable option, it is necessary to focus on thermal engineering calculation, thanks to which you can understand the effectiveness of a particular heat insulator, as well as its useful thickness.

Styrofoam

This material is most often used when insulating a wooden house with a brick cladding. Its main advantage is its low price and excellent thermal insulation qualities. Before installing the foam, the brick wall should be cleaned and leveled.

Styrofoam for insulation

Styrofoam for insulation Fastening is carried out using special bolts. They are screwed through the heat insulator into the masonry. Facade plaster is applied over the foam plastic.

Mineral wool

This insulation material has been in great demand for many decades. Mineral wool has excellent sound and heat insulation properties, provides decent ventilation and has low flammability. The disadvantages of mineral wool include a decrease in thermal insulation properties over time.

Mineral wool for insulation of a brick house outside

Mineral wool for insulation of a brick house outside The installation of the material takes place along a pre-fixed box of guides. For fastening, it uses anchor bolts.

Izolon

This modern material allows you to achieve maximum savings of heat inside the house. They produce a heat insulator in the form of rolls or a solution. To perform the insulation of a wooden house, it is necessary to use a liquid composition. Its injection is carried out by special pumps into the space between the wall and the brick. When using rolled material, a number of difficulties arise, so it is not used so often.

The use of isolon

The use of isolon Isolon is characterized by excellent impact strength, which has a positive effect on its service life. The only disadvantage of the heat insulator is that it has an unattractive appearance. So you have to take care of additional finishing.