One of the last stages of building a frame house is finishing it from the outside. For this, various materials are used, both natural and synthetic. Also, materials differ in cost, complexity of installation and their physical properties. How to choose the right material for cladding a frame house so that the ratio of quality and price is, if not ideal, then close to it? What kind of decoration can be done on your own, with your own hands, and which one is better to entrust to professionals?

Thermal panels for a wooden building

Thermal panels are becoming more and more popular, despite their high price. The reason for this is the ability to kill two birds with one stone - to insulate the facade of the house and at the same time bring the walls to an aesthetic appearance. Panel facades consist of clinker tiles, between which polyurethane insulation is laid.

For laying thermal panels, it is necessary to install special fasteners that run parallel to each other. A thermal panel is already easily installed on them, so a neat appearance of the exterior finish of the wooden frame is guaranteed.

Of the minuses: price and additional weight. Before installing, make sure yours is rated for the increased weight of the panels.

Great for places where the temperature in winter drops by more than minus 25. However, most often the panels are used for brick or block houses that do not have a layer of insulation.

Vinyl siding

Traditionally used for country houses or if you want to save money. At the same time, siding, in addition to a good price, has a number of other advantages:

- does not deteriorate, does not rot, does not decompose

- not subject to damage by bugs and rodents

- has a long service life

- easy to fit

- it is easy to care for - it is easy to clean and clean from dirt

- not afraid of moisture

In order for vinyl siding to look neat, it is necessary to align all the walls, on which the beams are then nailed. Leaving a small space between the wall and the material itself, we create an additional air gap that keeps the heat in the house.

Fake diamond

Artificial stone fell in love with the fact that when facing them with frame walls, the building looks much more presentable than just a wooden one. And when compared with natural stone, artificial even wins, since it is much easier to achieve a beautiful shade and structure in it than to pick up identical natural natural stones.

Artificial stone will also be lighter, which is much better for the foundation, which is often selected for a lightweight frame building. And besides, laying it is much easier and cheaper if you decide to entrust this matter to specialists.

Finishing with metal siding under a log makes the look of a frame house very interesting - it turns out a kind of hut from a fairy tale, and the finish is much stronger than wood and lasts much longer.

Metal siding is made of galvanized steel, after which the resulting "logs" are coated with a polymer coating that mimics the structure of a tree. The material does not rust, does not change its color in the sun, tolerates even strong temperature fluctuations.

Due to its qualities, metal siding under a log can be installed even in the winter season, which is fully consistent.

Metal siding is attached to a frame pre-installed on the wall.

Wooden lining

Clapboard made of wood is considered a traditional material for finishing the outside, especially if the house itself is a frame. Wooden lining looks good, while designers love it for the ability to easily and relatively inexpensively create the image of a Russian house that merges with nature.

Finishing the lining from the outside is quite simple and can be done by hand.

The only negative can be considered the susceptibility of natural wood to destruction. Wood easily absorbs moisture, changes its parameters - it can swell or shrink, besides, it is loved by bark beetles, bacteria that cause decay, etc. To protect the finish, new modern impregnations have been developed that not only prolong the life of the material, but also significantly increase .

At the same time, impregnations also improve housing safety indicators, making the wall paneling self-extinguishing and not supporting fire. For wood frame construction, this is very important.

Wall plaster

Finishing with plaster looks simple, but very neat, especially if it was done according to all the rules. The most important thing is not to miss a single stage in finishing.

In Russia, they don’t really like to plaster frame walls. The fact is that OSB-3, which is used to form a wall, can move, change size, the house can shrink and then cracks appear. With poor-quality plaster, it literally peels off after one season, lags behind the walls and looks extremely unaesthetic.

However, in America this problem was solved a long time ago by improving the technology of applying plaster to frame walls.

The structure of the improved plaster layer, which is needed for a frame building:

- On top of the waterproofing and drainage film, a galvanized steel plaster mesh is laid.

- The grid is fixed in a horizontal direction, overlapping.

- Fastening is carried out on roofing nails, on building half-inch brackets or with special fungi and ordinary wood screws.

- First layer of fibre-reinforced plaster. Drying time - 48 hours.

- The second layer is spread over a finer plastic plaster mesh. Drying time - 7 days.

- The third layer is decorative finishing plaster.

Do not forget: the minimum total thickness of the plaster layer must be at least 2.2 cm.

If you want to plaster in one layer, use a plaster mixture of Portland cement, white cement (lime) and sand. If you want to make it more durable, add fiber to the composition, which will reduce the likelihood of cracks.

After drying, the final layer of decorative plaster of the chosen color can be applied.

Blockhouse - imitation of timber

Another wooden material for finishing the outside of the house based on the frame. Outwardly, when laying, it resembles a beam, thanks to which a complete imitation of a log house-hut can be made from a frame cottage.

The blockhouse can be used both inside and outside the house, while the impregnations make the material fire resistant and inedible for bark beetles and pests. In addition, the block house does not crack over time, and is much stronger than rounded logs. However, with age, the appearance, of course, changes, because this, in truth, is the most common lining, which has only changed its shape.

There is a block house of different sizes on sale, a thinner one is suitable for interior decoration, and a wide one is suitable for exterior.

Finishing brick

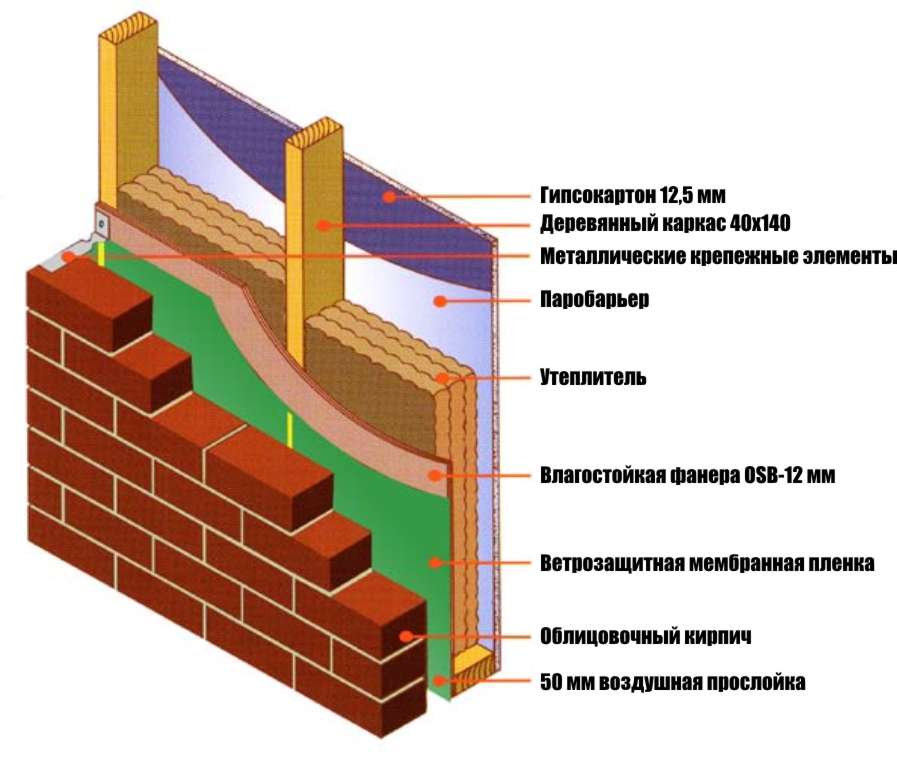

The frame house can be finished outside with a special facing brick. However, before finishing, you need to make sure that the foundation and walls will withstand. Despite the fact that the facing brick is hollow inside, the weight of the entire building will increase significantly after finishing.

The brick not only looks good, but also protects the wooden house from external environmental influences, extending the life of the frame.

The downside is the cost, since brick cladding on the outside is the most expensive cladding method.

Tiled cladding

The tile can have a different color and structure, it serves for a long time, does not deteriorate, does not change its parameters.

It is installed on a pre-made crate, while leaving a small air gap. Often this type of finish is considered suitable only for brick or block houses, since it will not work to put tiles on glue on wooden elements.

However, the technology still allows the use of tiles for wall decoration outside for a frame house - for this, self-tapping screws are used, which are driven into pre-drilled holes around the perimeter of the tile. Self-tapping screws are drowned in the seam. And the cost is about 1500 rubles. per sq.m.

Read about other ways of exterior decoration of a frame house.