The beam house is a modern finishing material that is widely used in suburban construction. Of course, a wooden country house impresses with its naturalness, closeness to nature, and the preservation of national traditions. However, building a house from a bar or log causes a lot of problems associated with the preservation of wood for a long time, the need for impregnation with special compounds. The block house allows you to create a complete feeling of natural wooden buildings, no matter what material is actually used.

Material feature

A bar-house (house) or, rather, a block-house with imitation of a bar is a finishing wood material that is most used when facing frame-type houses. By its design, such an element is a long wooden panel, on the edge of which a profile is made, which makes it possible to connect the panels to each other according to the tenon-groove system. In other words, a profile in the form of a longitudinal spike is formed on one edge, and a groove is formed on the opposite edge.

The lower surface of the block has a flat appearance, and the outer surface has a convex shape that imitates the corresponding wood element - lining, timber, log. When simulating a log, this surface is formed in the form of a half-cylinder, and to create the shape of a beam, this surface is straightened. The bar-house can be used for wall cladding, both outside and inside.

Material Advantages

It is very difficult to distinguish houses from a timber house in appearance from structures with walls in the form of a log house made of solid timber, although in fact the walls can be made of bricks, cinder blocks, foamed concrete, etc. Block house has a number of advantages compared to other materials:

- Good thermal insulation properties, resistance to temperature extremes.

- The panels are not subject to cracking, as they have undergone special drying.

- The block house is much lighter than a full-fledged timber and does not create excessive loads on the walls after cladding.

- Ecological cleanliness and harmlessness to humans, ensured by the use of natural wood.

- When carrying out the necessary impregnation, the material has sufficient durability.

- Ease of installation, possibility of repair and replacement.

- Cost savings compared to natural timber.

Material selection

Timber-houses can be made from different types of wood. Pine panels are the most widely used. This material has a relatively small number of defects in the form of knots and sufficient hardness. Significantly inferior to pine, spruce panels, although they have a lower cost. In terms of strength and waterproofing properties, larch stands out, but products made from it are much more expensive, which limits their use.

When choosing a material, special attention should be paid to the product grade, which has a letter designation. Low quality grade C is not recommended for residential applications. There are two types of material to choose from:

- Category A: the highest grade, made from the best wood and having a clear, high-quality structure and color. No more than 5 knots of small size are allowed per panel, with a total length of not more than 25 cm.

- Category B: products of medium quality, which may contain large knots (up to 5 cm long). However, the panels have a lower price, which may be the reason for choosing them.

The dimensions of the cladding blocks depend on the interior and whether the wall is sheathed - internal or external. Indoors, a bar-house with a width of 75-100 mm, a thickness of about 25 mm and a length of 2.5-3.5 m is usually used. Outside, it is better to use panels with a width of 14-26 cm, a thickness of 42-48 mm and a length of 5.5-6 m.

Do-it-yourself panel installation

When facing the walls of a house from a block house timber with your own hands, you will need the following tool:

- Bulgarian;

- electric drill;

- hacksaw;

- hammer;

- screwdriver;

- perforator;

- chisel;

- roulette;

- paint brush;

- level.

The timber-house is mounted on a crate fixed on the surface of the wall of the house. Here, one important advantage of such a cladding is manifested - the absence of the need for careful leveling of the surface of the wall base. It is strictly necessary to align the laths of the crate; in this case, the building level is used for control.

The crate is, on the one hand, an additional element that increases the complexity, but on the other hand, it makes it possible to provide a ventilation gap and install an additional heat-insulating layer in its cells.

The crate is usually made of a wooden lath (beam) 3x3 or 3x4 cm in size. Taking into account the fact that the panels are mounted horizontally relative to the ground to simulate a wooden frame, the crate is made in the form of vertical racks with a step of 45-80 cm. In order to align the bars, a control twine is pulled . Fastening to the wall is carried out with dowels using galvanized self-tapping screws.

After the installation is completed, the wooden elements are impregnated with an anti-rotten compound. Thermal insulation made of mineral wool or foam sheets is fastened between the racks of the crate. Instead of wooden beams for the manufacture of crates, you can use a standard aluminum profile.

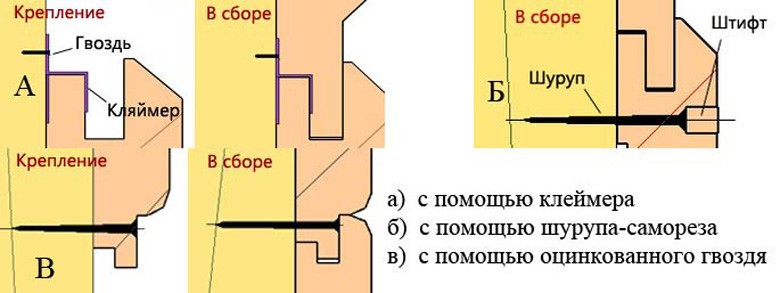

The installation of timber-house panels begins from the bottom row. The subsequent panel with its spike along the edge enters the groove of the bottom panel and is fixed. Fastening to the crate is done using galvanized self-tapping screws or nails. At the attachment points, it is recommended to pre-drill a hole for fasteners to prevent cracking of the board. At the corners of the house, a special patch strip is installed, masking the junction of the ends of the panels.

Facing the walls of the house with a timber-house creates a complete imitation of a wooden frame, which provides an attractive design. Along with the aesthetic appeal, the necessary quality, thermal insulation and reliability of the entire structure are ensured.

More articles on this topic: